You all know Koenigsegg (hopefully), but most of you have probably not heard about its sister company, Freevalve.

Freevalve Engine – What Is It, And How Will It Change The Car Industry

Well, prepare to be blown away, because they have unveiled a production specification engine that has no camshafts. If the 1980’s had VTEC as the top technology for valve control, and the 1990s turned to smarter fuel injection, culminating with current direct injection systems in the late 2000s, Freevalve is the engine technology of the future.

Just like the technological revolutions that came before it, Freevalve is about to cross another barrier through the introduction of flexibility instead of compromise.

Variable valve technologies exist today, but none of them is close to the possibilities introduced by this engine. The greatest part about it is that dramatic changes do not have to come to internal combustion engines to suit the new tech, but retrofitting is currently too costly to be considered.

Just like other engineers have focused on developing cylinder deactivation and variable compression or displacement technologies, the folks at Freevalve have worked on what’s known as the top end of the engine.

Koenigsegg found that valve operating technology had a lot more room for development, so the company was founded to handle the particular purpose.

Let’s go to the oily bits of the Freevalve technology, which was revealed today in production form.What does Freevalve do differently?

As its description stated, Freevalve is a “camless engine.” The rather incredible classification for a piston-operated motor is the secret behind its revolutionary character. It does not need camshafts because the valves are operated individually. Each valve is free from its “sisters,” thus the Freevalve name.

The idea is to make the internal combustion motor more efficient in all its operating phases. Conventional camshafts had to include a compromise, and that often involved sacrificing fuel economy for performance (the opposite applies), but also trading low-end torque for limited power at high rpms.

With the new tech, engineers will have the possibility to make a motor efficient at any rpm, without any worry of a rough idle, poor acceleration, or the failing fuel economy.

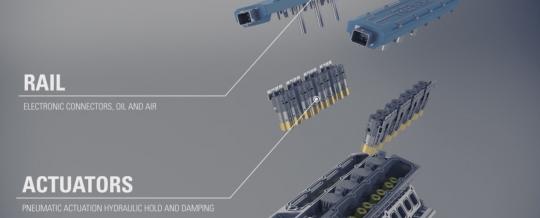

It sounds like an impossible dream, but Koenigsegg’s sister company has done what the Swedes kept exhibiting in prototype form on various vehicles. Instead of camshafts, each valve is controlled by an individual actuator, which in turn is electronically controlled.How much better is it, and is it more expensive than conventional camshaft setups?

Freevalve says that its system uses 10% less energy than a traditional valvetrain solution. That percentage is the part that “robs” vital power from an engine to help it run, just like ancillary components operate. Fuel efficiency might be improved by more than 10%, but the biggest gain comes from emission reduction.

For example, a spark-ignited engine (read gasoline unit) can eliminate its pre-catalytic converter, while fuel economy will be close to that of a diesel power plant.

The resulting power unit will be cheaper than the equivalent diesel, Freevalve says. Diesel units can get the system as well, and they will be able to use more cost-competitive after-treatment systems for their emissions.

In short, the first tens of thousands to hundreds of thousands of engines with this tech will be more expensive than a conventional equivalent, but will end up being as affordable as regular units. The best part is that the engines will be more efficient than traditional ones, while matching or exceeding their power and torque figures.

What happens if it fails?

The fans of old-school cars are probably wondering what the hell happens to the owner of a car with a Freevalve engine when things go bad. There’s no denying this, every engine can break down, and any design can have a minor flaw that could lead to failure if left unattended.

Freevalve says that this engine will be able to run as normal if one or more actuators fail, but the power level at high rpms will be slightly reduced. If things go wrong, you will still have a “limp mode,” which is available even if 75% of the actuators were to fail.

It is unlikely for as many actuators to fail at the same time, and it is ironically more reliable than a conventional valvetrain, because any regular engine will leave you stranded if its valvetrain suffers a failure as significant as 75%. Moreover, if just one of your valves is “misbehaving,” you lose more than just power at high rpms.

Even in the case of a dramatic flop, which leads to a full rebuild for a conventional engine, the Freevalve engine will not need this, because it will only stop running, without the valves "meeting" the pistons. What was that cam belt service interval, again?Is this more than fully variable valve timing?

A short answer would be yes, because each particular valve can have a different “lift,” both in time and position. It can also have a different timing setting, but the primary position is that the location of each valve is continuously monitored (i.e. in real time) to a precision level that is 1/10 of a millimeter (0.00393 inches).

The actuators that move the valves are operated with exceptional accuracy, significantly superior that what one might find in a conventional engine.

Furthermore, they are designed to have a lifetime that is equal to a modern internal combustion motor. No maintenance is needed, and the company says it has simulated “hundreds of millions of cycles” with “no measurable wear.

The use of h

ydraulic-electronic actuators for valves also eliminates the need for timing gear, a timing cover, a timing chain or belt, a camshaft (duh!), and even a wastegate for turbocharged engines. The latter is a detail that popped up with the introduction of the first production-ready Freevalve unit.When can I get one?

Fortunately for the average Joe, this technology will not be launched in a Koenigsegg. At least, we do not believe that is going to happen, because Freevalve has revealed the first engine of this kind in its production specification under the hood of a Qoros 3 hatchback. If the name means nothing to you, do not worry, it is a new car brand launched by the Chinese at Chery a few years ago, but with no significant sales offensive.

Freevalve has been working on this technology since the year 2000, so a few more months or even years will probably not be felt.

The promise is a gasoline engine that is more silent, more fuel efficient, and at least as powerful as its conventional equivalent. Put a better torque curve and a manufacturer customizable power delivery, and you get a package worth waiting.