In recent years, four-wheel drive systems have become increasingly popular, especially in cars that usually wouldn’t have 4wd systems.

Four-Wheel Drive: How GKN Driveline's On-Demand 4WD System Works

Carmakers have introduced four-wheel drive to their customers even in cars with transverse-mounted engines, and performance versions of some compact cars have been available with this system.

At first, the Haldex system was the norm for these vehicles, but it was not as good as a conventional all-wheel drive solution.

A British company called GKN Driveline introduced the world to its all-wheel drive solutions, and they seem to be popular with automakers these days, so we decided to explain how it works.

What’s interesting about the all-wheel drive system proposed by GKN is the torque vectoring capability without the use of the vehicle’s brakes, along with the possibility of decoupling the rear wheels to save fuel.

The system sold by Swedish company Haldex worked on the same principle as the latter feature, but it did not perform as well as the GKN solution.

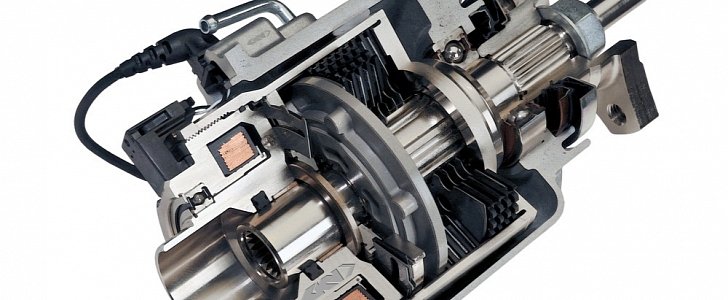

What you are probably asking yourself right now is what the difference between the Haldex system and GKN’s solution is. Well, the difference comes in the configuration of the driveline. Instead of a central differential, GKN’s solution uses a “Power Transfer Unit” instead. From there, the two-piece or three-piece driveshaft sends the power to the rear differential.How does GKN’s system go from front-wheel drive to all-wheel drive?

The trick is in the rear differential that features an electronically-controlled clutch pack. In the case of the new Ford Focus RS, it can deliver up to 70% of available power to the rear wheels. Thanks to another clutch pack, it can perform torque vectoring functions without using the vehicle’s brakes, thus enhancing cornering speed.

Naturally, the rear differential is linked to the front part of the driveline through a set of prop shafts that are disconnected using the Power Transfer Unit.What is torque vectoring and how does it work?

Torque vectoring is the ability of a drive system to control how much of the available power is sent to an individual wheel. Torque vectoring systems used to work with the help of the braking system on most cars, but GKN Driveline developed a multi-clutch system that can achieve the function without touching a vehicle’s brakes.

The Range Rover Evoque, Ford Focus RS, Audi RS Q3, and other GKN-equipped vehicles have this feature. Naturally, the system exists in other environments, but still relies on the vehicle's brakes to achieve the torque vectoring function.

The latter is based on the same components used by traction control systems: speed sensors in each wheel, electro-mechanical control of brake pressure for each wheel, and a computer that compares input and readings with pre-programmed data. The computer decides the optimal course of action based on the algorithm it works on.What did Haldex-equipped cars have to do to achieve this?

The Haldex system was capable of torque vectoring using the vehicle’s brakes and a rear Torsen differential. This happened to the fourth-generation Haldex system, and on particular cars. This system was more expensive for automakers to offer when compared to the GKN Driveline solution, so it was available on premium models with high outputs, and even then it was an optional feature.How GKN’s system works

On the Ford Focus RS, for example, the GKN system has a Power Transfer Unit in the front final drive, and a Rear Drive Module that uses the “Twinster” twin clutch system. This allows the carmaker’s engineers to configure the drive system for several driving modes, and to offer torque vectoring functions across all the speeds the vehicle is capable of attaining.

Thanks to their Twinster, the guys at GKN can apply torque to one or two wheels independently on the rear axle, without the use of brakes to slow the other wheel. It is all done with clever clutches that are electronically controlled. The vehicle’s four-wheel drive system knows how and when to do this with the aid of speed sensors in each wheel, which work together with sensors that monitor steering input, throttle action, and the vehicle’s speed.

These systems already existed in modern cars, so the people at GKN did not have to invent them or introduce them at extra cost for the carmakers that chose their system. Going back to how the Twinster system works: it predicts the need for power to the rear wheels by using an algorithm based on configurations developed during testing and delivers power to the mentioned wheels whenever necessary.What is a Power Transfer Unit and what does it do?

The Disconnect All-Wheel Drive system from GKN Driveline is prevalent in the small SUV and crossover class because of its compact size. It works with the PTU as mentioned earlier. This device is linked to the final drive differential of the gearbox and contains a fast-disconnect device and a dedicated brake. The latter can stop all of the components upstream of the Power Transfer Unit’s hypoid gears.

Meanwhile, an electro-mechanically actuated clutch disengages the rear wheels from the driveshaft to save fuel. Since everything is electro-mechanically activated, the on-demand all-wheel drive reacts faster than viscous-couplings. What controls the all-wheel drive system from GKN Driveline and other similar suppliers?

Modern vehicles have numerous computers on board, and the ones with all-wheel drive have a dedicated driveline control unit. As we explained earlier, it monitors operating parameters and determines if all-wheel drive is necessary based on predefined values and situations.

According to GKN Driveline, their system can reconnect the all-wheel drive system in just 300 milliseconds (0.3 seconds). That's the average time it takes the human eye to blink, according to scientists.

It can take up to 400 milliseconds to blink, so some human eyelids are slower in operation than GKN Driveline’s reengagement of its all-wheel drive system. For another analogy to help you put this into perspective, it takes the human brain 200 milliseconds to recognize specific emotions in facial expressions. What is an EMCD?

GKN Driveline uses an Electromagnetic Control Device for its all-wheel drive systems. The EMCD solution replaces viscous-coupling systems with the help of an electromagnet. The latter generates a magnetic field that is used to control the clutch torque by adjusting the amount of current delivered to it based on vehicle inputs and a dedicated control algorithm. Instead of reacting to a situation, it is proactive based on readings from sensors.

Usually, this type of four-wheel drive system is found in passenge

r cars and SUVs that are not meant for serious off-road applications. The latter require a lockable center and rear differentials, and even a lockable front differential to ensure grip in rugged terrain, at low speeds.

However, these conventional systems are cumbersome and costly when compared to the solution provided by GKN Driveline. That is why such systems will probably never be available for compact cars, as they require more room and weigh more than the system described in this article.GKN’s Winter Testing Facilities in Arjeplog, Sweden