Engine mounts are among the components that nobody talks about until they break.

Engine Mounts – What They Do And Why You Should Replace Them

Just like their name explains, engine mounts have the role of keeping the power plant in place inside the engine bay. They are usually a component that has rubber and metal, and they are screwed into the engine block and various parts of the body to ensure that things do not move more than intended.

Motor mounts vary in shape, size, and appearance because they have to suit different engine layouts, but they all function on the same principles. Just like other components, engine mounts are made to provide a balance of multiple characteristics to suit the general population.

Automakers have the technology to make performance dedicated motor mounts, but doing so will make the cars fitted with them uncomfortable at idle or at various rpm ranges.

Because of that reason, motor mounts are softer than they could be, and they tend to act like “cushions” that do their best to absorb vibrations and unwanted movement.The reason for engine mounts

As the throttle is applied, the engine shifts around the bay, and engine mounts have the role of dampening this phenomenon. Depending on engine design, engine mounts might have to absorb more or fewer vibrations. If that wouldn't happen, the vehicle would shake like a washing machine operating on full power during the spin cycle.

Unfortunately for performance enthusiasts, stock engine mounts are not even close to the level of rigidity desired from a sports car. Because of this, some of the torque generated by the engine is lost in the form of vibrations that are absorbed by motor mounts. However, if they were to be replaced with all-metal units, other elements of the vehicle would be affected.

If engine mounts would not be as soft as most of them are designed to be, the response of the power plant could be improved, especially when pulling away from idle. The behavior of the car when going from consistent throttle application to max throttle could also see an improvement after the change.Active engine mounts

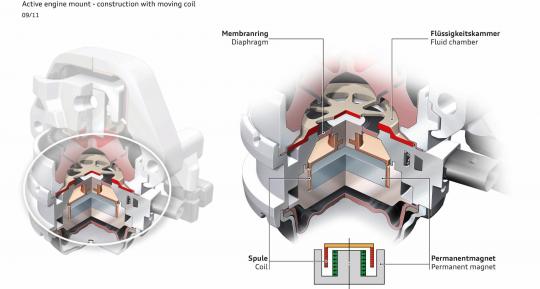

Some automakers have employed engine mounts with liquid in them, which have a moving coil that makes them softer or harder depending on predetermined settings. The respective coil operates magnetorheological fluid, which does the whole magic with the help of an electromagnet.

Other active engine mounts have a vacuum-operated valve that controls the fluid differences between two chambers, and adjusts it according to throttle operation. The 1990 Honda Accord had an active engine mount system, and its role was to increase comfort at idle and at revs close to 1,000 rpm.

Some active engine mounts are configured to produce a vibration counter at a particular frequency, which covers up the known vibration pattern of the power plant. Active engine mounts used to be available only on premium cars that are not that affordable, but volume automakers employ them these days as well.

Fortunately for performance enthusiasts, aftermarket engine mounts are available for a variety of cars. Some of them are offered in different levels of rigidity, which is a solution that was designed to satisfy a broad range of needs and applications. Some customers will want to have their daily drivers to get slightly stiffer engine mounts, while others will seek a dedicated solution for track toys.Aftermarket engine mounts

At this point, we must note that fitting different engine mounts will change the level of comfort in your vehicle, and not necessarily in a good way. Unfortunately, it is hard to say just how significant the change will be overall.

It is evident that fitting the stiffest engine mounts you can buy will make your car unpleasant at idle, but you might have a tricky time at figuring out what is the best configuration of engine mount stiffness for your needs. Consult a professional tuning shop for adequate advice on the matter before buying upgraded aftermarket engine mounts.

Take your time to think about the replacement engine mounts you want to fit, as they will be tricky to fit, and the labor billed by a mechanic to install them will be consistent. Do not change a single engine mount if it is the only one that has visibly failed.

If you do this, expect the other mounts to fail because they will be subjected to more vibrations than before, on account of the fact that the new engine mount withstands more tremor than its predecessor did.Replacing engine mounts

The common symptoms of a failed engine mount involve increased engine noise, and perceivable power plant vibrations in the passenger compartment. Usually, the rubber parts of the engine mounts fail, especially when exposed to years of fluctuations. In the case of liquid-filled engine mounts, their failure is similar, but the causes behind it might be different.

In both instances, an engine that has broken mounts will make more noise in first or reverse gears. Other signs include noticeable vibrations at idle, which get more intense when the engine is started cold.

Replace your engine mounts soon after you encounter any of these symptoms, because they might translate into problems with the transmission mounts. In extreme circumstances, you cannot exclude the complete failure of engine mounts, which will lead to damaging the engine and engine compartment.

Regardless of the automobile you drive, the decision to fit uprated engine mounts should bring a performance enhancement. If you start off with classic motor mounts and want to drive your car on the track, you are bound for a massive improvement with the use of quality aftermarket components that come with upgraded specifications.

Enthusiasts who have fitted uprated engine mounts claim that their cars now have improved throttle response, along

with better acceleration. In cars with rear-mounted engines, a handling improvement is also expected, because even the smallest movements of the power plant can be felt in dynamic driving conditions, and this upgrade should make the vehicles that get it more predictable and stable.Demonstration of active engine mounts